- Главная

- Каталог товаров

- Ткани продажа, текстильные изделия

- CARDING MACHINE

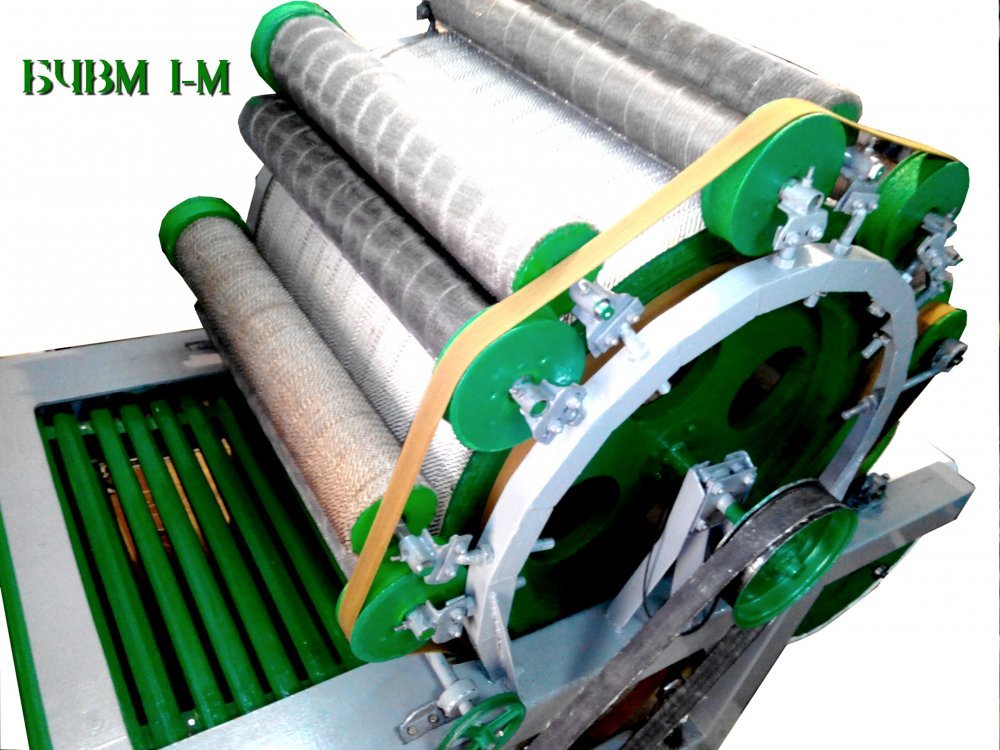

CARDING MACHINE |

||

|

Поделитесь страницей в Социальных сетях

|

Carding Machine BCHVM 1-MMulti-processing equipment conversion fibrous textile materials: rough, semi-coarse, polutonkorunnyh wool padding polyester, and others. To form BLANKET formation. For workpieces on the boots, producing yarn. For uniform mixing of different breeds and types of textile materials. To remove the trash from the wool. Loosening wool. To upgrade the old (flattened) blankets. For lapping and alignment. Dimensions: height 165 cm, 220 cm long, 120 cm wide. Motor: 1,5 kW; single phase ~ 220V, gear 1 * 40, 400 W / h 3000 r / min. Throughput: 6-15 kg \ hour, depending on the material being processed and the flow rate on the receiving belt. Working width 700 mm, Yield: canvas size 1600H700 mm, thickness 10 mm. (1.5 kg) wool (or ribbon having a predetermined width). The rollers of the machine equipped with hard combing surface (Card fillet), their position is adjustable. Principle of operation: Wool passed through the carding valichnogo mechanism fiber separation and removal of trash and unnecessary compounds, the output is grebёnuyu tape combed fibers in one direction. brushing: dog, sheep, camel wool, angora, down, padding polyester and other fiber materials. Areas of use: Suitable for yarn, BLANKET reservoir filler for pillows, mattresses, sweatshirts, for the manufacture of blanks on the felt for yurts, boots, heaters, for BLANKET formation and other products. The standard version is made without external protective structure, but put the needs of (an additional order 18t.rub +) Emergency stop. When entering foreign (medium, large) objects on the working surface of the machine comes alarm reset the tape drive, thereby mechanism stops. The machine already comes with all the settings. Вас также могут заинтересовать Ballu Machine Клапан противопожарный BMFDO(60)-MB(230)-ф225-к круглое сечениеНормально открытые и нормально закрытые клапаны предназначены для блокировки распространения пожара и продуктов горения по воздуховодам, шахтам и каналам систем вентиляции и кондиционирования зданий иBallu Machine Клапан противопожарный BMFDC(120)-MBE(230)-ф200 круглое сечениеНормально открытые и нормально закрытые клапаны предназначены для блокировки распространения пожара и продуктов горения по воздуховодам, шахтам и каналам систем вентиляции и кондиционирования зданий иBallu Machine Клапан противопожарный BMFDO(90)-MB(230)-ф225 круглое сечениеНормально открытые и нормально закрытые клапаны предназначены для блокировки распространения пожара и продуктов горения по воздуховодам, шахтам и каналам систем вентиляции и кондиционирования зданий иBallu Machine Клапан противопожарный BMFDO(60)-MB(230)-ф200-к круглое сечениеНормально открытые и нормально закрытые клапаны предназначены для блокировки распространения пожара и продуктов горения по воздуховодам, шахтам и каналам систем вентиляции и кондиционирования зданий иBallu Machine Клапан противопожарный BMFDO(60)-MB(230)-ф180-к круглое сечениеНормально открытые и нормально закрытые клапаны предназначены для блокировки распространения пожара и продуктов горения по воздуховодам, шахтам и каналам систем вентиляции и кондиционирования зданий и

Внимание! Информация по CARDING MACHINE предоставлена компанией-поставщиком ООО "КардМаш". Для того, чтобы получить дополнительную информацию, узнать актуальную цену или условия постаки, нажмите ссылку «Отправить сообщение». |

|

|

О проекте

Поставщики машин и оборудования

Профессионалы строительного рынка

|

Редакция портала не несет ответственности за достоверность информации, опубликованной компаниями в новостях, статьях, описании товаров и в рекламных материалах.

|